Yesterday was a good day to catch up on some studio chores, as the kiln was completing a bisque firing and the rain poured down.

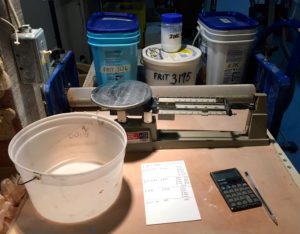

First on my list was the weighing of ingredients for my cone 04 clear glaze, then adding water, and mixing and sieving them. I left the bucket for a while and turned to mixing plaster. You’ll see that I do take the precaution of wearing a mask when dealing with ceramic materials.

I left the bucket for a while and turned to mixing plaster. You’ll see that I do take the precaution of wearing a mask when dealing with ceramic materials.

I’ve never used plaster in my studio but I have decided that it is time to have an effective way of storing partially completed pots. For decades I’ve wrapped pieces under construction in dry cleaner plastic, hoping that they remain suitably leather hard for me to continue cutting and joining a day or a week later.

I have been told that a layer of plaster in the base of a lidded plastic tote, kept damp, will remain so indefinitely. Leather hard work left in there will stay workable for ever. My main concern is to keep extruded bird spouts/bills for future use. I often produce a dozen or so and can only use a few at a time. So last week I bought a couple of clear, lidded plastic totes in two sizes.

To make sure I got the ratio of water to plaster correct and to remind myself of the process I put a request on Facebook ‘Clay Buddies’ and I had several very useful replies. Thank you to potters Jane Williamson and Denise Melinda Irwin and others who took the time to describe in detail how they go about making plaster. The video below is very helpful too, so thanks to Tim See.

I left the plaster to set up while I went out to the kiln shed to check on the glaze and I found that there was a thick solid layer at the bottom of the bucket. Aha! I remembered my pottery teacher Fred Owen using the word thixotropic to describe this phenomenon, but checked Google to make sure I remembered the remedy properly. ‘A teaspoon of Epsom Salts dissolved in a cup of warm water, added slowly while stirring the glaze’ is the suggestion.

At first it wasn’t very successful but last thing in the day I stirred it again, very thoroughly, scraping the hard stuff with my fingers and it became beautifully smooth. Today it was still all liquid and I sieved it into the previous remaining glaze. Fingers crossed! June suggests that the remedy could safely be used once or twice more if necessary.

The phenomenon is, I think, similar to what happens with liquefaction, i.e. when solid land becomes liquid during an earthquake, and you can see it when you mix cornstarch with water. My pottery text books explain that it has to do with electrolytes. I’m simply happy to have a solution… rather than a solid.

Tomorrow I’ll be able to open the kiln and start waxing my jugbirds prior to glazing. I’m aiming to have a completed firing ready for a much-anticipated visit of my Austin niece and three of her friends. One is taking pottery lessons so they’ve all plotted to spend some time in my studio next weekend.

Pingback: Clay Blog Review: September 2016 - Pottery Making Info